Home /

NEWS /

How to Customize Welded Wire Mesh Sheets

Feb 06, 2026

Welded wire mesh sheets are widely used in construction, infrastructure, industrial, agricultural, and security applications. While standard sizes are suitable for many projects, custom welded wire mesh sheets are often required to meet specific structural, environmental, or design requirements.

This article explains how to customize welded wire mesh sheets, covering key parameters, customization options, common applications, and how buyers can work efficiently with manufacturers to achieve optimal results.

1. Why Customization Matters for Welded Wire Mesh Sheets

Every project has unique requirements. Standard welded wire mesh may not always match:

Structural load calculations

Local construction standards

Installation conditions

Environmental exposure

Customization ensures welded wire mesh sheets deliver precise performance, improved durability, and cost efficiency, especially for large-scale or specialized projects.

2. Key Parameters to Customize Welded Wire Mesh Sheets

Wire Diameter

Wire diameter directly affects strength and load-bearing capacity.

Common customization options:

Light-duty: 2.0–3.0 mm

Medium-duty: 3.0–5.0 mm

Heavy-duty: 5.0–8.0 mm

Selecting the correct wire diameter ensures structural reliability without unnecessary material costs.

Mesh Opening Size

Mesh opening size determines flexibility, strength, and application suitability.

Typical custom mesh openings include:

Small openings for concrete reinforcement

Medium openings for fencing and enclosures

Large openings for industrial or security applications

Accurate mesh spacing is critical for meeting engineering drawings and standards.

Sheet Size and Dimensions

Welded wire mesh sheets can be customized to match project layouts.

Common sheet sizes:

Standard panels (e.g., 2×3 m, 2.4×6 m)

Non-standard dimensions for prefabricated structures

Custom sheet sizes reduce on-site cutting, installation time, and material waste.

3. Surface Treatment Options for Custom Welded Wire Mesh

Black Welded Wire Mesh

Black welded wire mesh is commonly used for:

Interior construction

Concrete reinforcement

Precast components

It offers high strength at a lower cost but requires proper concrete coverage for corrosion protection.

Galvanized Welded Wire Mesh

Galvanization significantly improves corrosion resistance.

Customization options include:

Electro-galvanized welded wire mesh

Hot-dip galvanized welded wire mesh

Hot-dip galvanizing is preferred for outdoor and humid environments due to its thicker zinc coating.

PVC Coated Welded Wire Mesh

For enhanced durability and aesthetics, PVC coating can be applied over galvanized mesh.

Benefits include:

Dual corrosion protection

Resistance to chemicals and moisture

Optional colors for decorative or visible installations

4. Welding Strength and Quality Control Customization

The quality of welded intersections is critical.

Customization can include:

Adjusted welding current and pressure

Reinforced weld points for heavy loads

Testing according to customer specifications

Reliable weld strength ensures the mesh performs as designed under stress.

5. Customization Based on Application Scenarios

Construction and Concrete Reinforcement

Customized welded wire mesh sheets are widely used in:

Floors and slabs

Foundations and walls

Pavements and infrastructure

Specifications are often based on structural calculations and engineering drawings.

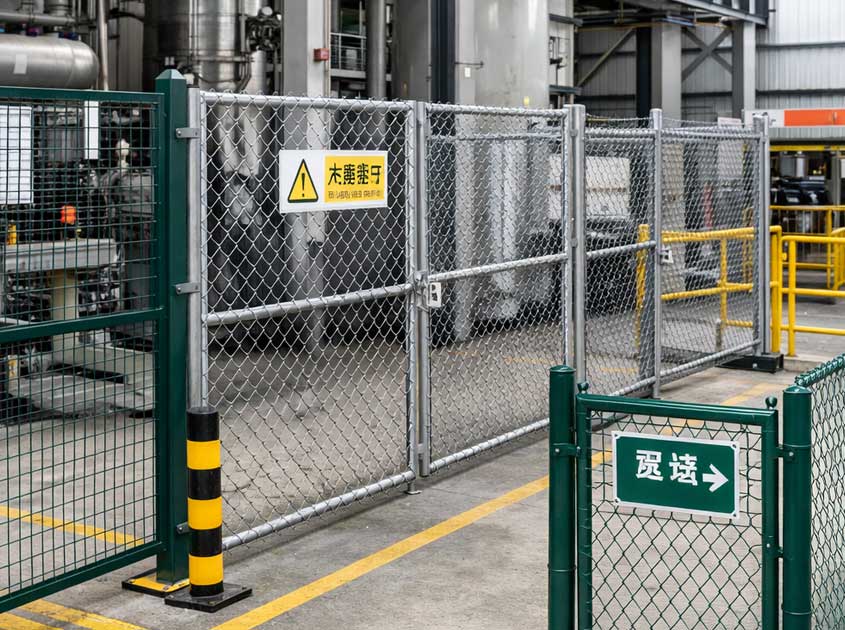

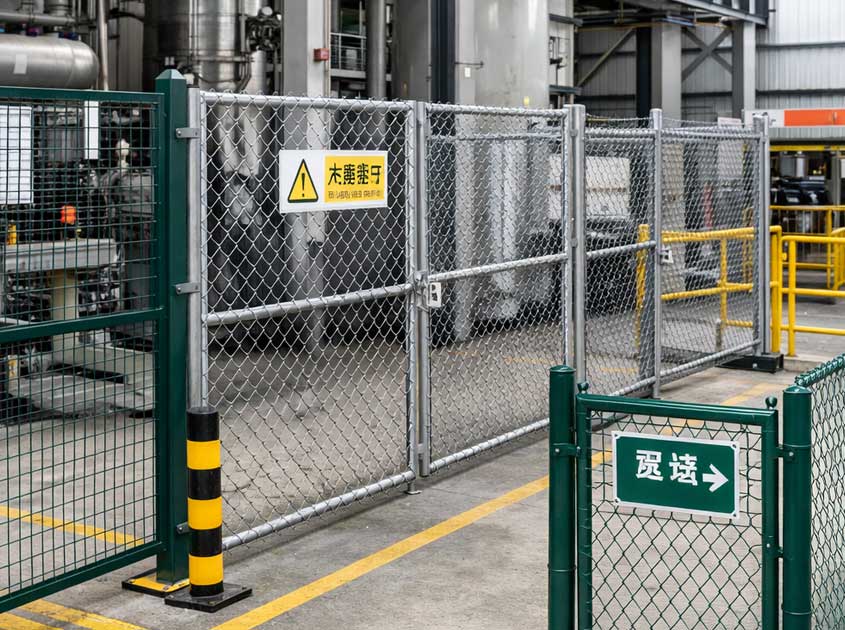

Security and Fencing Projects

For fencing applications, customization may include:

Thicker wire diameters

Specific panel heights and widths

Galvanized or PVC coated finishes

These features enhance strength, safety, and longevity.

Industrial and Agricultural Applications

Industrial and agricultural projects often require:

Larger sheet sizes

High tensile strength

Enhanced corrosion resistance

Customization ensures suitability for harsh working environments.

6. Compliance with International Standards

Customized welded wire mesh sheets can be manufactured to meet:

ASTM standards

EN standards

ISO quality requirements

Compliance is especially important for international construction projects and government tenders.

7. Export Packaging Customization

Proper packaging protects welded wire mesh sheets during transportation.

Common export packaging options include:

Steel-strapped bundles

Wooden pallets or crates

Waterproof wrapping for sea freight

Customized packaging ensures safe delivery and efficient unloading.

8. Information Buyers Should Provide for Custom Orders

To ensure accurate production, buyers should provide:

Wire diameter and mesh opening size

Sheet dimensions and quantity

Surface treatment requirements

Application environment

Reference drawings or standards

Clear communication reduces production errors and lead time.

9. Lead Time for Custom Welded Wire Mesh Sheets

Customization may slightly affect production time.

Typical timelines include:

Standard customization: 10–20 days

Complex specifications or large quantities: 20–30 days

Experienced manufacturers can optimize production schedules to meet project deadlines.

10. Why Choose a Chinese Manufacturer for Custom Welded Wire Mesh

China is a leading global supplier of welded wire mesh.

Key advantages include:

Advanced welding and galvanizing equipment

Flexible customization capabilities

Competitive manufacturing costs

Extensive export experience

Professional Chinese manufacturers support custom projects from design to delivery.

Conclusion

Customizing welded wire mesh sheets allows buyers to achieve better performance, higher efficiency, and long-term reliability. By selecting the right wire diameter, mesh size, surface treatment, and packaging, welded wire mesh can be precisely tailored to project needs.

For global contractors and distributors, working with an experienced welded wire mesh manufacturer ensures consistent quality, smooth communication, and successful project outcomes.

Pre:What Is the Best Fence Mesh for Security in the Middle East?

Next:none