Home /

NEWS /

What Are the Common Packing Methods for Wire Mesh Export?

Dec 22, 2025

For international buyers sourcing

wire mesh products from China, packing is far more than a logistical detail. Proper packing plays a critical role in protecting products during long-distance transportation, ensuring smooth customs clearance, and reducing damage or losses upon arrival.

This article explains the most common packing methods for wire mesh export, their advantages, and how professional Chinese wire mesh manufacturers select the right packing solutions for different products and markets.

Why Proper Packing Is Critical for Wire Mesh Export

Wire mesh products are usually heavy, bulky, and made of metal, which makes them vulnerable to:

Deformation during loading and unloading

Corrosion caused by moisture and salt air

Surface damage during long sea voyages

Safety risks during handling

Well-designed export packing helps buyers:

Receive products in good condition

Reduce claims and disputes

Improve unloading efficiency

Meet local warehouse and project requirements

Roll Packing for Wire Mesh

Plastic Film or Waterproof Paper Wrapping

For wire mesh supplied in rolls, the most common packing method is:

Inner wrapping with waterproof paper or plastic film

Outer reinforcement with woven bags or shrink film

This method is widely used for welded wire mesh rolls, woven wire mesh, and galvanized mesh.

Advantages:

Cost-effective

Protects against moisture

Easy to handle and store

Roll Packing with Pallets

For higher-value or heavier rolls, pallets are often added.

Rolls are wrapped first

Then fixed onto wooden or steel pallets

Advantages:

Better protection during forklift handling

Reduced deformation

Faster loading and unloading

This method is popular for export to Europe, North America, and Australia.

Panel Packing for Wire Mesh

Bundle Packing with Steel Strips

Wire mesh panels are commonly packed in bundles.

Panels are stacked evenly

Tied with steel strips

Wrapped with plastic film if needed

Advantages:

Simple and strong

Suitable for heavy panels

Efficient for container loading

This method is often used for welded mesh panels and fencing panels.

Palletized Panel Packing

For projects with strict handling or safety requirements, pallet packing is preferred.

Panels are stacked on pallets

Fixed with straps

Wrapped with stretch film

Advantages:

Enhanced protection

Reduced risk of edge damage

Suitable for warehouse storage

Fence and Special Product Packing

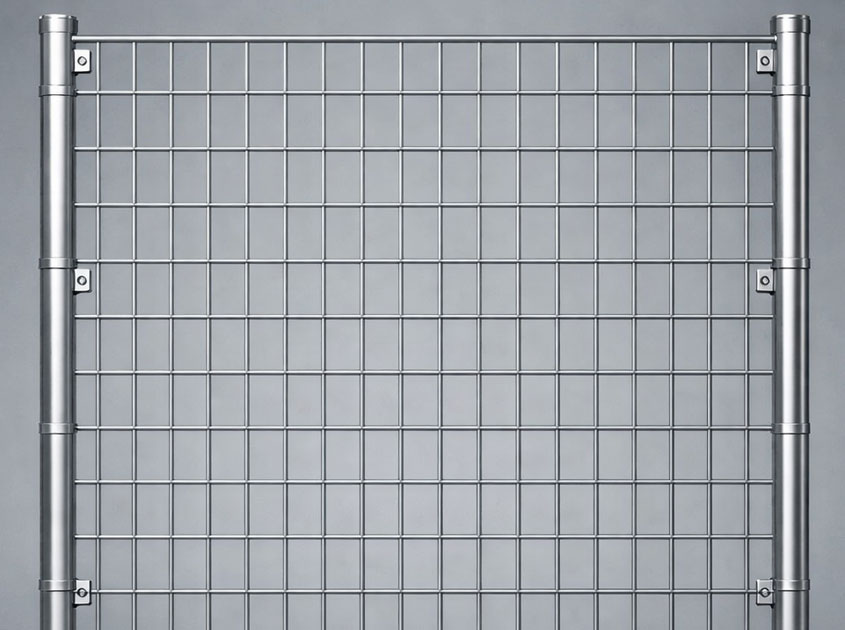

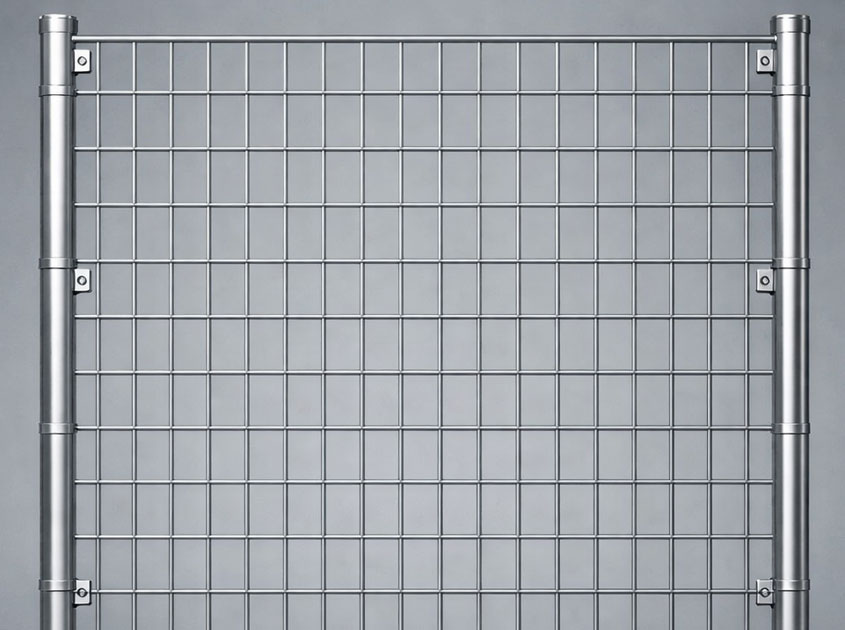

Fence Panels and Posts

Fence systems usually include panels, posts, clamps, and accessories, which require organized packing.

Common methods include:

Panels bundled or palletized

Posts packed separately

Accessories packed in cartons

Clear labeling helps buyers identify each component quickly upon arrival.

Gabions and Heavy Mesh Products

Gabions and heavy wire mesh are usually packed as:

Folded flat bundles

Tied with steel wire

Optional pallet support

This method minimizes space usage and reduces shipping costs.

Crate and Wooden Case Packing

For high-value or precision wire mesh products, wooden crates or cases may be used.

Applications include:

Stainless steel wire mesh

Filter mesh

Precision industrial mesh

Advantages:

Maximum protection

Suitable for long-distance sea transport

Reduced risk of deformation

Wooden packing typically complies with ISPM 15 standards for international shipping.

Anti-Corrosion Packing Measures

To prevent rust during sea transportation, especially for galvanized or black wire mesh, manufacturers may apply:

Anti-rust oil or vapor corrosion inhibitors (VCI)

Moisture-absorbing desiccants

Sealed waterproof wrapping

These measures are particularly important for shipments to humid or coastal regions.

Customized Packing for Different Markets

Export packing often needs to meet local market or customer requirements.

Customization may include:

Private labeling and branding

Barcodes and batch numbers

Language-specific markings

Special pallet sizes

Professional manufacturers work closely with buyers to meet these needs.

How Manufacturers Choose the Right Packing Method

Experienced Chinese wire mesh manufacturers select packing based on:

Product type and weight

Shipping method (FCL or LCL)

Destination country

Customer handling equipment

Cost-efficiency and safety balance

The goal is to provide adequate protection without unnecessary cost.

Common Packing Mistakes to Avoid

Buyers should be aware of common issues such as:

Insufficient moisture protection

Weak strapping for heavy bundles

Overpacking that increases shipping costs

Poor labeling that causes unloading confusion

Choosing an experienced export manufacturer helps avoid these risks.

Conclusion

Packing is a crucial part of wire mesh export that directly affects product quality, transportation safety, and customer satisfaction. From roll packing and panel bundles to palletized and crate packing, each method serves specific products and shipping conditions.

By working with a professional Chinese wire mesh manufacturer that understands international logistics and export standards, buyers can ensure their wire mesh products arrive safely, efficiently, and ready for use.

Pre:How to Ensure Wire Mesh Fence Quality When Buying from Overseas Suppliers?

Next:Best Wire Mesh Fence Solutions for Construction Projects in South America